Manufacturing 101: Tips for Streamlined Operations

The complexities of modern manufacturing can challenge even the most seasoned professionals. Delving into the multifaceted world of production and operations, it’s imperative to understand the intricacies that foster an efficient and effective environment. Streamlining manufacturing processes not only optimizes productivity but also enhances profitability. In this article, we’ll explore key strategies to refine your manufacturing practices, ensuring your operations are as smooth and efficient as possible. Keep reading for valuable insights and actionable tips.

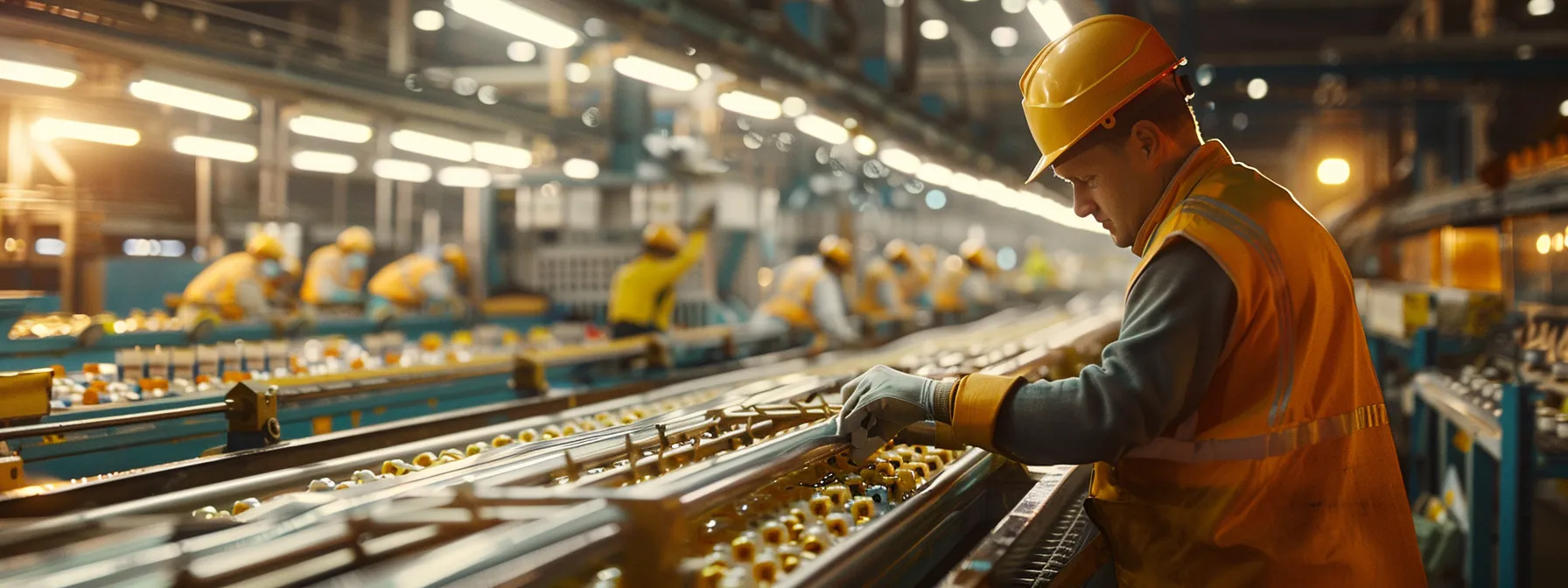

Understanding the Basics of Manufacturing Operations

A successful manufacturing operation relies on seamless coordination, from sourcing raw materials to final production. Managing each stage effectively minimizes bottlenecks and ensures the smooth flow of goods. Key to this is the use of tools like manufacturing ERP software, which streamline operations, optimize resource allocation, and prevent costly inefficiencies.

staying compliant with industry regulations safeguards legal and workforce integrity, while adopting sustainable practices appeals to eco-conscious consumers. Companies that prioritize compliance and eco-friendly methods not only avoid disruptions but also enhance their market reputation and competitive edge.

Implementing Lean Manufacturing for Efficiency

Lean manufacturing is a methodology that focuses on reducing waste and enhancing productivity by focusing on processes directly contributing to the end product. It can lead to significant cost savings and operational efficiency. Key principles include just-in-time production, continuous flow, and takt time, which ensure production keeps pace with customer demand without overburdening the system.

Employee empowerment is also crucial, as frontline workers often have the most insight into process improvements. Open communication and feedback can help businesses tap into valuable knowledge for streamlining operations. 5S, a workplace organization method, complements lean manufacturing by promoting cleanliness and organization, improving focus, safety, and productivity.

Utilizing Technology for Enhanced Production Management

Modern manufacturing operations are increasingly leveraging technology to improve efficiency and productivity. Automation and robotics have revolutionized factory floor tasks, allowing human workers to focus on more complex tasks. Data analytics and machine learning provide insights into manufacturing processes, enabling proactive decision-making and smoother production cycles. Manufacturing ERP software integrates all facets of operations, from supply chain management to customer relations, enabling a more synchronous organization.

ERP solutions provide visibility and control over every aspect of the entity. The Internet of Things (IoT) has also become a pivotal role in manufacturing, offering real-time monitoring and control through connected machines and systems. This connectivity enhances operational transparency and facilitates remote management, a growing necessity in a globalized manufacturing network.

Maintaining High Quality Control Standards

Maintaining rigorous quality control is crucial for manufacturing excellence, as it ensures products meet customer expectations and regulatory requirements. This commitment not only strengthens brand reputation but also minimizes costly returns and repairs. A robust quality control process starts with stringent sourcing criteria for raw materials and regular inspections at various stages of production.

Standardized testing procedures and clear criteria for acceptance or rejection establish a consistent baseline for product quality and reliability. Investment in training is essential, with workers being educated on quality standards and empowered to halt production if defects are detected. Feedback loops are vital for continuous improvement, as it helps manufacturers stay on top of customer satisfaction levels and align product development with customer needs.

Fostering a Culture of Continuous Improvement

A culture of continuous improvement is crucial for a forward-thinking manufacturing operation, as it encourages innovation and adaptability to stay competitive in a fast-paced market. This culture involves actively seeking ways to enhance all aspects of production and encourages employee engagement to contribute ideas for improvement.

Establishing metrics for success, such as production speed, waste reduction, and energy efficiency, helps teams set specific goals and make the success of improvement efforts measurable and transparent. Adopting flexible processes is essential for staying nimble, as it allows businesses to quickly adjust to new technologies, changes in consumer demand, or economic shifts. This adaptability must be ingrained in the company ethos to foster a culture of continuous improvement.

Overall, streamlining manufacturing operations is a dynamic and multifaceted endeavor. Incorporating lean principles, optimizing with advanced technology, maintaining stringent quality controls, and nurturing an innovative, improvement-focused culture are the cornerstones of a thriving manufacturing environment. By addressing each of these areas, manufacturers can position themselves for sustained success in a competitive global marketplace.